$77 each plus GST

Minimum order 8

For all orders email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Minimum order 8

For all orders email: This email address is being protected from spambots. You need JavaScript enabled to view it.

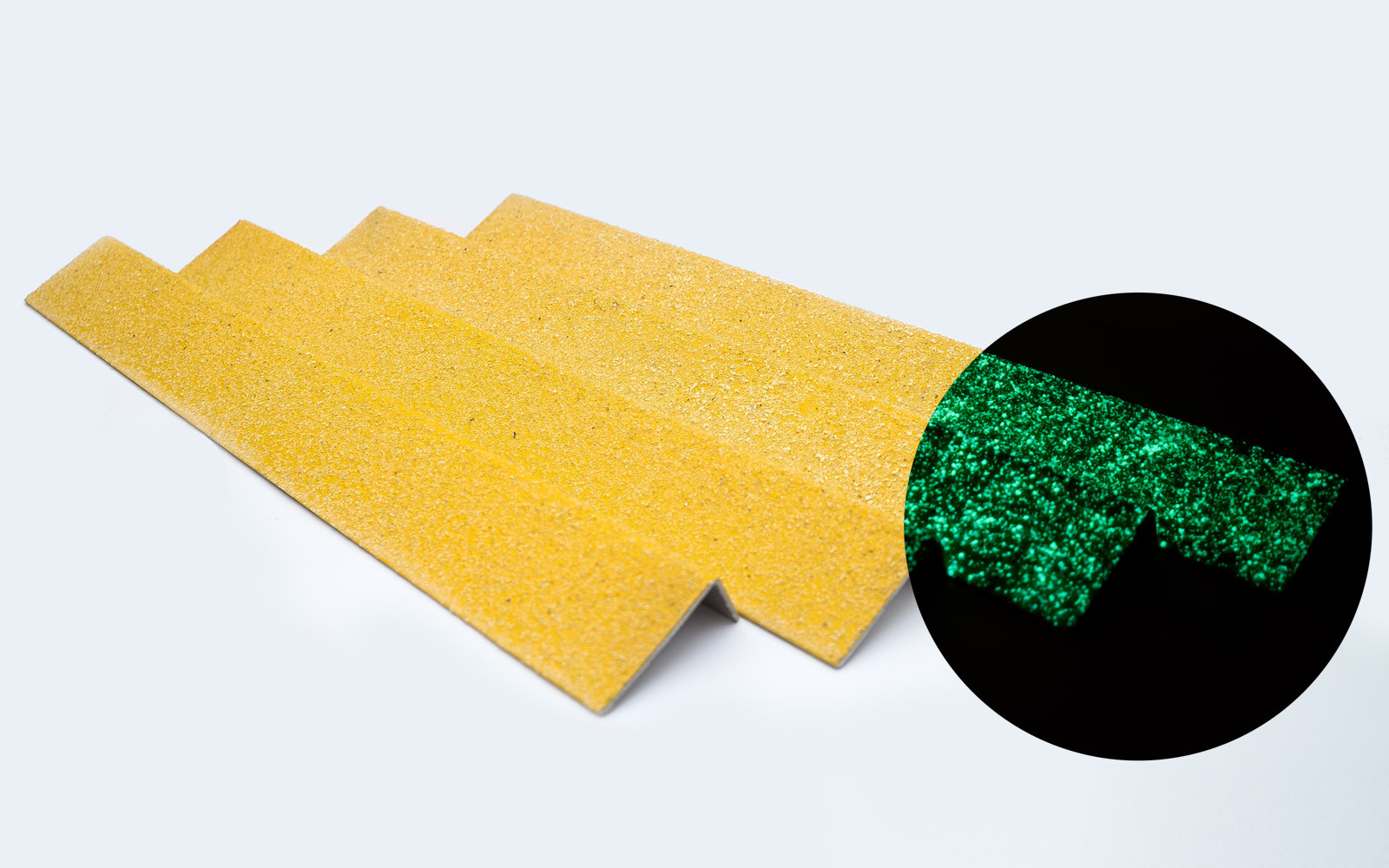

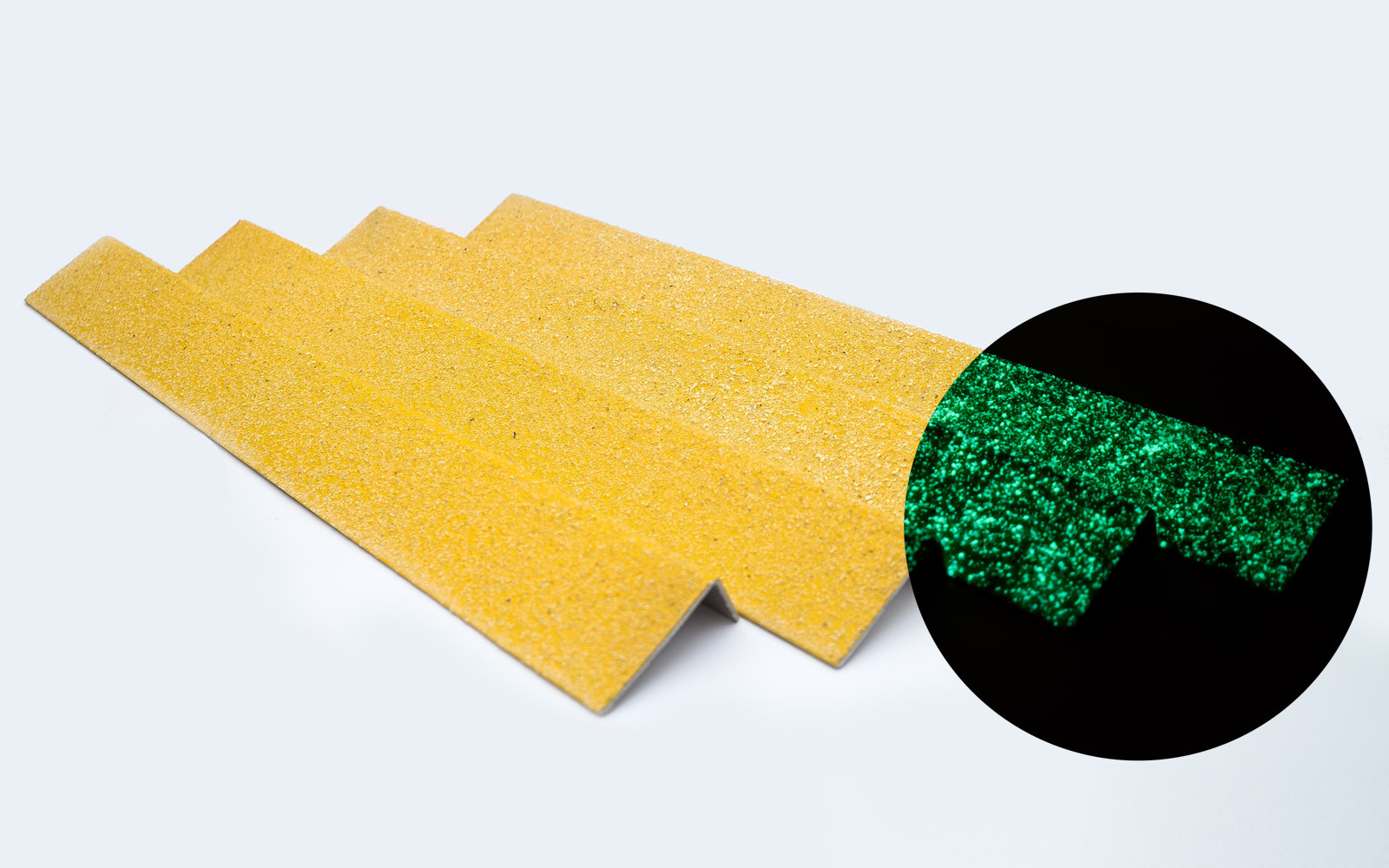

Moon Deck Luminous FRP Stair nosings are like no other stair nosing on the market. Its innovative luminous aggregate emits a passive form of glow for up to 12 plus hours with the sufficient ability to regenerate. It is an excellent form of emergency lighting for all work, health and safety in any industry in the event of power outage or smoke inundation.

Moon Deck Luminous Stair Nosings comprise of totally safe biologically and chemically inert natural minerals. They harness natural energy from any form of incandescent or daylight including shaded areas.

Moon Deck Stair Nosing’s are pre-formed FRP extrusion that has an innovative anti-slip aggregate interlocking coating that provides an excellent slip-resistant and ultra hard wearing surface. These products are NATA certified Australian slip resistant standards AS4586:2013.Class P5, the highest standard achievable.

Moon Deck Stair Nosings are designed for easy installation onto most step edges. The fact that they are supplied as a finished product means that it can accept traffic immediately after installation thus keeping disruption to a minimum. This product is ideal for do it yourself installations and is simply adhered and mechanically fixed into place.

(SN900FRP)

When installing Moon Deck ‘Glow Step’ Luminous Anti-Slip Stair Nosing’s, we strongly recommend that PPE (personal protective equipment) is worn at all times. PPE Day operations- Normal requirements but not limited to:

PPE required for particular tool. Ensure all PPE meets relevant Australian Standards. Inspect, and replace PPE as needed. Implement a project/task specific SWMS (Safe Work Method Statement), as per WHS legislation.

Disclaimer

This document contains material to assist in meeting work health and safety obligations under the Work Health and Safety Act 2011. Although every effort has been made to ensure the accuracy of this information at the time of publication, it is provided as guidance only and does not provide legal advice on meeting your obligations.

Surface preparation if using a suitable adhesive shall be in accordance to the manufacturer’s specification the stairs should be dry and clean and free from any loose and defective material. If there are areas that are damaged these should be repaired so that the surface is flat and even. Undertake a dry fit of the nosing to ensure that it sits flat and is the correct size.

The Stair Nosing’s should be cut externally or in well ventilated areas. If any further trimming is required, we recommend the use of a jigsaw, preferably fitted with a tungsten carbide blade or hand grinder. Dust residue can be disposed of using normal waste disposal methods. Masonry diamond cut –off blades work well, wet or dry.

Timber Surfaces

Place the Stair Nosing onto the desired surface location. Then use a masonry drill bit marginally larger than the selected fixing head to drill to countersink the top of the Moon Deck Aggregate surface in the desired locations. Do not exceed further than 2.0mm allowing the majority of the fixing to be below surface level. We would recommend that there are approximately every 150mm over the distance of stair nosing; and a minimum 10G x 38mm screw. However this would depend on the usage and installation location.

Once the countersunk holes have been drilled, follow through with a pilot hole diameter recommended as per the selected fixing size. Additional High strength polyurethane adhesive can be used (if required) to add extra grip to the underneath the stair nosing and also reduce any ‘Drumming’ that may result with timber shrinkage or general movement.

Metal Surfaces

Place the Stair Nosing onto the desired surface location. Then use a masonry drill bit marginally larger than the selected fixing head to drill to countersink the top of the Moon Deck Aggregate surface in the desired locations. Do not exceed further than 2.0mm allowing the majority of the fixing to be below surface level. We would recommend that there are approximately every 150mm over the distance of stair nosing. However this would depend on the usage and installation location. Once the countersunk holes have been drilled, follow through with a pilot hole diameter recommended as per the selected fixing size.

There are many options for fixing; rivets or stainless metal thread nut and bolts.

Additional High strength polyurethane adhesive can be used (if required) to add extra grip to the underneath the stair nosing and also reduce any ‘Drumming’ that may result with general movement.

Concrete and Masonry Surfaces

Place the Stair Nosing onto the desired surface location. Then use a masonry drill bit marginally larger than the selected fixing head to drill to countersink the top of the Moon Deck Aggregate surface in the desired locations. Do not exceed further than 2.0mm allowing the majority of the fixing to be below surface level. We would recommend that there are approximately every 150mm over the distance of stair nosing. However this would depend on the usage and installation location. Once the countersunk holes have been drilled, follow through with a pilot hole diameter recommended as per the selected fixing size. We recommend ‘Ramset’ Easydrive Branded 30mm Masonry anchor or similar.

Additional High strength polyurethane adhesive can be used (if required) to add extra grip to the underneath the stair nosing and also reduce any ‘Drumming’ that may result with general movement.

Adhesive

Whilst mechanical fixings are all that is required to secure the stair nosing, wherever possible, the application of an appropriate high strength polyurethane adhesive such as ‘Sikaflex-291’ Branded Adhesive or simular will provide the following benefits: A secondary fixing in the event that the mechanical fixings should fail. A barrier against the "Drumming" noise that may be created when fitting over the existing substrate that is uneven.

Important preparation to the underside of the stair nosing must be carried out prior application as per manufacturer’s requirements for maximum bonding.

We recommend a minimum abrasion of the surface with 80-120 Grit sand paper to roughen up the surface, followed by a light solvent wipe with Acetone to remove any waxes and residues. Apply a 5-8mm bead of high strength gap-filling adhesive randomly over the underside of the stair nosing and in horizontal or diagonal stripes. Immediately press the stair nosing firmly to the substrate to ensure adequate transfer of adhesive. A firm bond will be achieved in about one hour under normal circumstances and conditions. Secure with the mechanical fixings and allow the adhesive sealant to cure before allowing excessive traffic to use the areas.

Open Steel or Composite Grid Mesh Walkway and Stair Panels

Stainless steel or zinc plated saddle clips and domed head bolts can be located from various engineering supply chains for the correct fixtures suitable for a variety of mesh sizes.

The security of the fixings / adhesives should be checked on a regular basis. Circumstances will vary, based upon the volume of foot traffic, impact etc. but, as a guide, monthly inspections would be advisable in highly trafficked areas. Although Moon Deck Glow Steps are extremely resilient to dirt and contaminations they will, as with most other things, become dirty. Dry dirt and debris can easily be removed using a stiff brush and should be carried out on a regular basis.

If the Glow Step stair nosings have been subjected to spillages or the dirt has become embedded, detergents can be used. Scrub using a mild general biodegradable detergent with warm water and a suitable brush. Scrub the affected areas until clean. This can then be washed off with clean water or by using a power washer. Where circumstances allow, the Stair Nosing’s can be high pressure power washed without causing harm by maintaining a lance distance kept at a minimum distance of 300mm and not exceeding 3000PSI.

Careful attention should also be taken if the Glow Step has been additionally fixed or sealed with a suitable adhesive as very high pressure power washing or repeated power washing could cause damage and delaminating to sealants and adhesives.

| SKU | SN900FRP |

| Thickness | 3-4mm |

| Shipping Weight | 0.7500kg |

| Shipping Width | 0.070m |

| Shipping Height | 0.030m |

| Shipping Length | 0.900m |

| Shipping Cubic | 0.002025m3 |

| Unit Of Measure | ea |